italcer group

The mission of Italcer Group is to create high-quality products for consumers, customers and architectural professionals, combining design, beauty and innovation in a sustainable perspective, with respect for the environment and natural resources.

The vision of Italcer Group is to be a global leader in the field of designer ceramics and luxury bathroom furnishings via an innovative and sustainable industry.

of the Group

THE GROUP OPERATES

(4 IN SPAIN, 8 IN ITALY)

INVESTMENTS IN R&D

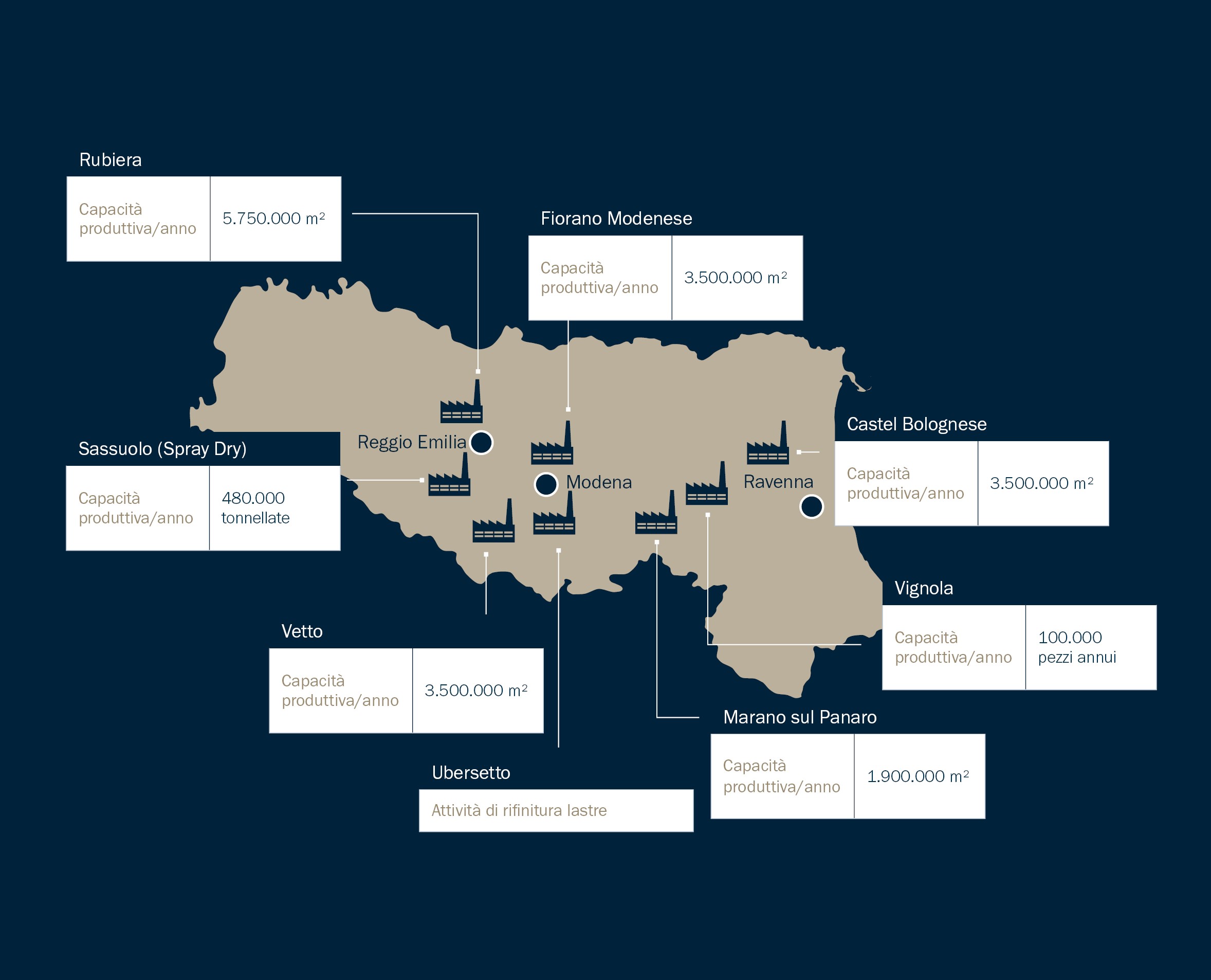

This facility, consisting of six buildings, is located in the Municipality of Rubiera, in the Province of Reggio Emilia. The site covers a total surface area of about 100,000 m2 and it employs 110 people, 83 in production and 27 in logistics. The plant is owned by the Group and is specialised in the production of medium and large-sized ceramic products. Its annual production capacity is around 5.75 million m2.

This plant, located on the border between Formigine and Fiorano Modenese, in the Province of Modena, covers a total surface area of 56,900 m2. The plant employs 66 people (65 in production and 1 in logistics) and is specialised in the production of small-format ceramics (XS and S) as well as Elios Ceramica ceramics for swimming pools. Through recent investments to modernise certain production lines for Industry 4.0, the plant is able to produce large formats (100 cm x 100 cm) for indoor and outdoor use, adopting H20 technology (20-mm thick products). The facility has an annual production capacity of approximately 3.5 million m2.

The industrial building in Formigine (Modena), which became part of the Group through the acquisition of Ceramica Fondovalle, has a total surface area of 36,000 m2. The plant employs 33 people (24 in production and 9 in logistics) and is specialised in ceramic finishing (cutting, grinding, lapping and rectification). Recent investments have led to the modernisation of the polishing line with ‘supershine’ technology to increase production and improve yield. Logistics activities are carried out at the site.

The Marano sul Panaro (Modena) complex, which became part of the Group in 2022 through the acquisition of Ceramica Fondovalle, has a total surface area of around 26,900 m2. The plant employs 50 people and is specialised in the production of large ceramic surfaces (L and XL). The plant has an annual production capacity of approximately 1.9 million m2.

The Castel Bolognese (Ravenna) plant is owned by Ceramiche di Romagna S.r.l. and is currently managed by the Group under a lease agreement. The plant, which covers a total surface area of about 83,000 m2, employs 104 people (98 in production and 6 in logistics) and is specialised in the production of extra-small, small and medium-sized ceramics, both for indoor and outdoor use, using H20 technology. Recent investments in the plant have led to the opening of a third production line and the installation of a 2 MW cogeneration plant. The facility has an annual production capacity of approximately 3.5 million m2.

The industrial site located in the Municipality of Vetto d’Enza covers a total surface area of around 132,000 m2.

This production site, specialised in the production of large and extra-large ceramics, employs 79 people (77 in production and 2 in logistics) and has recently invested in a new picking line, a cogeneration plant with heat recovery and the production of a new extra-large 24 cm x 150 cm format. The annual production capacity of the plant is approximately 3.5 million m2.

This industrial site, located in the Municipality of Sassuolo (Modena), covers a total surface area of about 45,000 m2 and employs 26 people. The plant is dedicated to the production of spray-dried mixtures. With an annual production capacity of about 480,000 tonnes, the plant is used mainly for the Group’s own production, but it also supplies third-party companies in the sector. A 3.2 MW cogeneration plant was recently installed to reduce energy costs, along with a grinding plant for fired ceramic waste and a new wet grinding plant for raw materials to improve the efficiency and sustainability of the production process.

This industrial site, located in the municipality of Vignola (Modena), occupies an area of about 1000 m2 and is specialised in the production of artistic ceramics, for an annual production capacity of about 100,000 pieces. The plant employs 8 production workers and 1 logistics officer.

SPANISH PRODUCTION FACILITIES

The plant in Figueroles, Spain, is owned by the subsidiary Equipe Cerámicas. It comprises three industrial buildings and warehouses with a total of eight production lines. The plants are specialised in the production of glazed and unglazed ceramic products and have an annual production capacity of approximately 7,000,000 m2. The plant employs 210 people, including 24 in the logistics department.

The Onda plant is specialised in glazed and non-glazed ceramic products. It employs 38 people and manufactures customised products to meet the customisation specifications required by customers. Its annual production capacity is about 155,000 m2.

STEP BY STEP

La Fabbrica S.p.A. was founded in Castel Bolognese (Ravenna). Its high quality, combined with design and creativity, quickly became the key factors for recognition and success, supported by a widespread sales network across Italy and abroad. In a short time, the La Fabbrica brand established itself as a benchmark of Italian ceramic excellence.

Always staying ahead of the latest trends, at Cersaie 2014, the AVA brand introduced the large format to the market. Extraordinary Size is an ambitious project featuring some of the world's largest porcelain stoneware slabs, measuring 320×160 cm with a thickness of 6 mm. This project includes a wide variety of collections, available in multiple designs and sub-formats.

Elios Ceramica S.p.A., based in Fiorano Modenese (MO), was acquired in August 2017 and subsequently merged into the parent company

Italcer S.p.A.

Devon&Devon S.p.A., acquired in October 2017, is a world leader in high-end bathroom furniture with a classic-contemporary style.

Rondine S.p.A., founded in 1961 in Rubiera (RE), became part of Italcer Group in October 2018 and adopted the name Italcer S.p.A. in 2019.

With the acquisition of Rondine, the Sassuolo-based company Spray Dry S.p.A. (wholly owned by Rondine since 2005) also became part of Italcer Group. The company produces atomised powder, which first allowed Rondine, and then Italcer Group, to make an important qualitative leap by internalising the entire ceramic production cycle.

Italcer USA was founded in December 2018 to serve the American market with dedicated product lines.

In August 2019, Bottega S.p.A. became part of Italcer Group, subsequently merged by acquisition into Italcer S.p.A.

In March 2021, the Italcer Group expansion and internationalisation strategy continued with the acquisition of Equipe Cerámicas S.L.U., founded in 1999 in Figueroles, Castellón, which today is the world’s leading company in the small floor and wall tile market.

In October 2022, Italcer Group completed its product portfolio with the acquisition of Ceramica Fondovalle S.p.A., a company founded in 1962 and today a market leader in the production and sale of large and very large porcelain stoneware slabs.

In late 2023, Italcer Group expanded further by acquiring Terratinta Group S.r.l. benefit company, a company specialising in high-end furnishing surfaces based in Fiorano Modenese in the Province of Modena.

La Fabbrica S.p.A. was merged into Italcer S.p.A. SB, and the historic brands were unified under a new single brand, LA FABBRICA AVA. The brand offers a wide range of porcelain stoneware products, from large slabs to small formats, combining Italian heritage, innovative design, certified quality, and top-tier performance.